The quest for sustainable infrastructure has led researchers to explore groundbreaking solutions in construction materials. Among these, self-healing concrete stands out as a revolutionary approach to addressing the perennial problem of cracks and structural degradation. At the heart of this innovation lies the careful selection of bacterial strains capable of precipitating calcium carbonate to seal fractures autonomously. The screening process for these microbial candidates is both an art and a science, demanding a nuanced understanding of microbiology, materials engineering, and environmental compatibility.

Microbial candidates for self-healing concrete must meet stringent criteria. Not only do they need to survive the harsh alkaline environment of concrete (pH 12-13), but they must also remain dormant for years until activated by water ingress through cracks. Researchers have focused primarily on alkaliphilic spore-forming bacteria, with genus such as Bacillus showing particular promise. The selection process begins with isolating strains from extreme environments like soda lakes, volcanic ash deposits, and even within old concrete structures where surviving bacteria have naturally adapted to alkaline conditions.

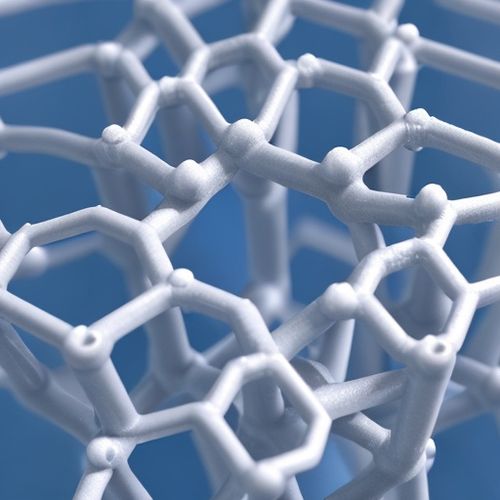

The metabolic activity of these bacteria holds the key to effective self-repair. When water enters a crack, it triggers the germination of bacterial spores. The bacteria then metabolize calcium lactate or other nutrients incorporated into the concrete mix, producing calcium carbonate as a byproduct. This biomineralization process effectively fills the crack from the inside out. Recent studies have revealed that certain Bacillus pseudofirmus strains can precipitate calcite crystals at rates exceeding 4mm per day under optimal conditions, with the resulting material achieving compressive strengths comparable to original concrete.

Beyond basic survivability and metabolic function, researchers must consider the long-term viability of bacterial spores within the concrete matrix. Some strains demonstrate remarkable persistence, with studies showing viable spores after 200 days in simulated concrete environments. However, the real challenge lies in maintaining viability over decades - the typical lifespan of concrete structures. Advanced encapsulation techniques using biodegradable polymers or porous ceramic carriers have shown potential in protecting bacterial spores while allowing controlled nutrient diffusion when needed.

The ecological implications of introducing bacteria into construction materials require careful evaluation. While most candidate strains are non-pathogenic and environmentally benign, their large-scale incorporation into buildings and infrastructure demands thorough risk assessment. Researchers are particularly interested in strains that are naturally occurring in urban environments, minimizing potential ecological disruption. Some studies have even explored using bacteria derived from concrete microbiome samples, ensuring perfect adaptation to the intended habitat.

Emerging techniques in high-throughput screening have revolutionized the selection process. Automated systems can now evaluate thousands of bacterial isolates for key parameters including sporulation efficiency, calcium carbonate yield, and alkaline tolerance. Machine learning algorithms analyze this data to predict long-term performance in concrete applications. This technological leap has enabled researchers to move beyond trial-and-error approaches to a more systematic exploration of microbial capabilities.

Field trials have provided crucial validation for laboratory findings. Several pilot projects across Europe and North America have incorporated different bacterial strains in real-world structures ranging from bridge decks to building foundations. These trials not only test healing efficiency but also evaluate practical considerations like mixing compatibility and effects on fresh concrete properties. Early results suggest that bacterial self-healing can extend structure lifespan by 20-30 years while reducing maintenance costs by up to 50%.

The economic calculus of bacterial self-healing concrete continues to improve as production methods advance. While early versions required expensive nutrient additives, recent breakthroughs have identified waste-derived alternatives like industrial byproducts that can serve as bacterial food sources. Simultaneously, optimized growth and sporulation protocols have reduced the biomass required per cubic meter of concrete. These developments are bringing the technology closer to price parity with conventional concrete while offering superior lifecycle performance.

Standardization efforts are underway to bring order to this rapidly developing field. International organizations are working to establish testing protocols for bacterial concrete, including standardized methods for assessing healing efficiency, long-term viability, and material compatibility. These standards will be crucial for gaining regulatory approval and building industry confidence in the technology. Meanwhile, patent landscapes are evolving rapidly, with both academic institutions and construction material companies staking claims to proprietary bacterial strains and delivery systems.

Looking ahead, researchers envision a new generation of smart infrastructure where biological and material systems work in concert. The careful selection of bacterial strains forms just one part of this broader vision, which may eventually include bacteria capable of sensing stress or environmental conditions. As climate change increases the demands on our built environment, such biologically enhanced materials may prove essential for creating resilient, sustainable infrastructure capable of self-maintenance in challenging conditions.

The journey from petri dish to pavement involves countless hours of meticulous research and testing. Each bacterial strain represents a potential solution to one of construction's most persistent challenges. As screening methods grow more sophisticated and our understanding of microbial-material interactions deepens, the promise of self-healing concrete moves steadily toward widespread reality, potentially transforming how we build and maintain the structures that shape our world.

By James Moore/Apr 19, 2025

By Joshua Howard/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Grace Cox/Apr 19, 2025

By Noah Bell/Apr 19, 2025

By Victoria Gonzalez/Apr 19, 2025

By Amanda Phillips/Apr 19, 2025

By Samuel Cooper/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Emma Thompson/Apr 19, 2025

By Thomas Roberts/Apr 19, 2025

By Lily Simpson/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Eric Ward/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Christopher Harris/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Lily Simpson/Apr 19, 2025