The realm of materials science has witnessed a paradigm shift with the emergence of high-entropy alloys (HEAs), a class of metallic materials that defy conventional alloy design principles. Among their many intriguing properties, the cryogenic toughness of HEAs has garnered significant attention from researchers and industries alike. Unlike traditional alloys, which often become brittle at low temperatures, certain HEAs exhibit remarkable resistance to fracture, making them promising candidates for applications in extreme environments.

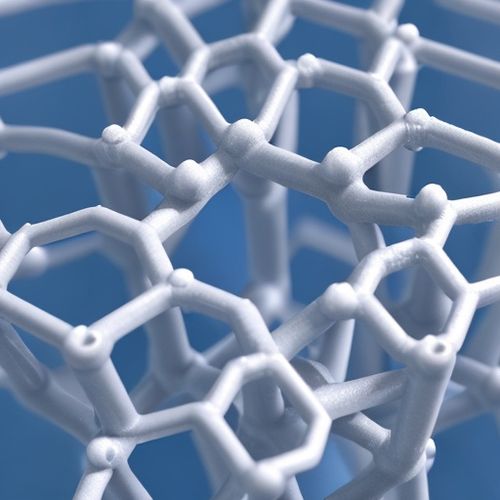

At the heart of this phenomenon lies the unique atomic structure of HEAs. Composed of multiple principal elements in near-equimolar ratios, these alloys possess a high configurational entropy that stabilizes solid solution phases. This complex chemical environment gives rise to severe lattice distortion, which plays a crucial role in their mechanical behavior. When subjected to cryogenic temperatures, the enhanced lattice friction and modified dislocation dynamics in HEAs contribute to their exceptional toughness.

Recent breakthroughs in HEA research have revealed that certain compositions maintain or even improve their fracture toughness as temperatures plunge. The CoCrFeMnNi alloy, often referred to as the Cantor alloy after its discoverer, has shown particularly impressive performance. At liquid nitrogen temperatures (-196°C), this alloy demonstrates a combination of high strength and ductility that surpasses most conventional structural materials. The synergy between deformation twinning and dislocation slip mechanisms appears to be responsible for this unusual temperature dependence.

The scientific community has proposed several explanations for the cryogenic toughness of HEAs. One prevailing theory suggests that the decreased thermal activation at low temperatures alters the deformation mechanisms in these alloys. While traditional materials see reduced dislocation mobility as temperature drops, HEAs benefit from the activation of secondary deformation systems. Twinning-induced plasticity (TWIP) and transformation-induced plasticity (TRIP) effects become more pronounced, providing additional energy dissipation pathways that prevent catastrophic failure.

Microstructural engineering has emerged as a powerful tool for optimizing the low-temperature performance of HEAs. Researchers have found that careful control of grain boundaries and phase distribution can significantly enhance cryogenic toughness. Nanoscale precipitates, when properly distributed, can pin dislocations and promote uniform deformation. Some studies have demonstrated that dual-phase HEAs combining face-centered cubic (FCC) and body-centered cubic (BCC) structures exhibit superior toughness retention across a wide temperature range.

The practical implications of these findings are profound. Industries operating in cryogenic environments, such as aerospace, energy storage, and polar technology, stand to benefit tremendously from HEA applications. Liquid natural gas (LNG) containment systems, superconducting magnet supports, and spacecraft components could all leverage the unique properties of these materials. The potential for weight reduction without sacrificing safety margins is particularly attractive for aerospace applications where every kilogram counts.

However, challenges remain in the widespread adoption of HEAs for cryogenic service. The complex composition of these alloys makes their processing and manufacturing more demanding than conventional materials. Issues such as compositional segregation during solidification and difficulties in thermomechanical processing must be addressed. Furthermore, the long-term stability of HEAs under cyclic loading at low temperatures requires thorough investigation before they can be certified for critical applications.

Looking ahead, the development of computational tools promises to accelerate the discovery of new HEA compositions with optimized cryogenic performance. Machine learning approaches combined with high-throughput experimentation are enabling researchers to explore the vast compositional space of HEAs more efficiently. These efforts may soon yield alloys specifically tailored for operation in the most extreme cold environments on Earth and beyond.

The study of HEA cryogenic toughness also provides fundamental insights into the physics of deformation in complex metallic systems. Each new discovery in this field challenges existing theories of plasticity and fracture, pushing the boundaries of materials science. As research continues, HEAs may not only find practical applications but also serve as model systems for understanding emergent phenomena in condensed matter physics.

From a broader perspective, the success of HEAs in cryogenic applications demonstrates the value of exploring unconventional material design strategies. Where traditional approaches often focus on incremental improvements to existing alloys, the HEA paradigm embraces complexity to achieve breakthrough properties. This lesson extends beyond materials science, offering a metaphor for innovation in other technological domains.

As winter approaches in the Northern Hemisphere, researchers worldwide continue their work to unravel the mysteries of HEA behavior at low temperatures. Their efforts may one day lead to materials that make extreme cold environments more accessible and safer for human exploration and industrial activity. The journey of HEAs from laboratory curiosity to engineering reality serves as a testament to the power of scientific curiosity and persistence in the face of material challenges.

By James Moore/Apr 19, 2025

By Joshua Howard/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Grace Cox/Apr 19, 2025

By Noah Bell/Apr 19, 2025

By Victoria Gonzalez/Apr 19, 2025

By Amanda Phillips/Apr 19, 2025

By Samuel Cooper/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Emma Thompson/Apr 19, 2025

By Thomas Roberts/Apr 19, 2025

By Lily Simpson/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Eric Ward/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Christopher Harris/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Lily Simpson/Apr 19, 2025