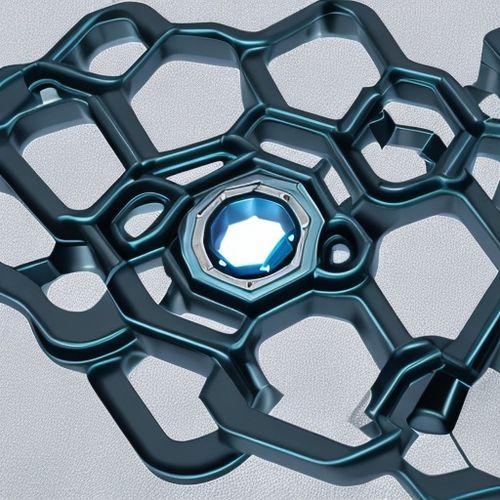

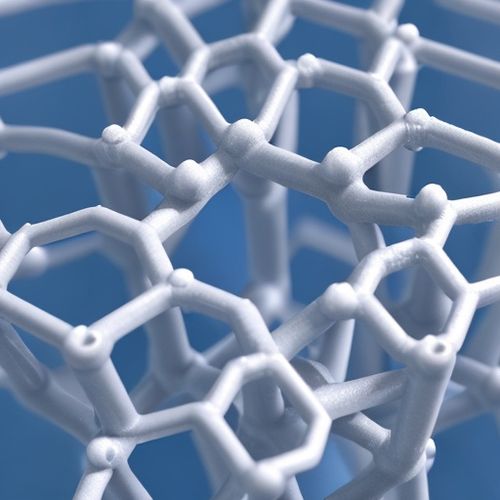

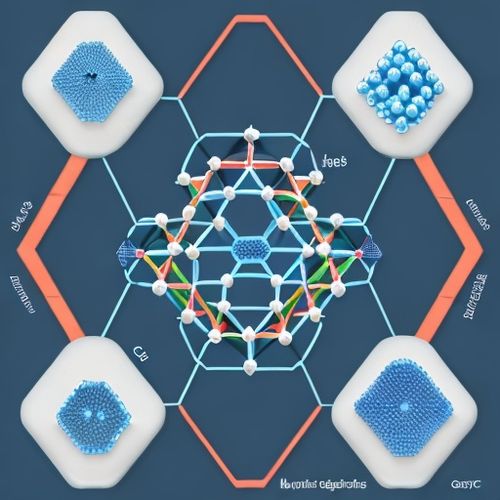

The world of material science has witnessed a revolutionary advancement with the emergence of Metal-Organic Frameworks (MOFs). These crystalline structures, composed of metal ions or clusters coordinated to organic ligands, have opened new frontiers in gas adsorption and storage. Their unparalleled porosity and tunable chemical properties make them ideal candidates for applications ranging from carbon capture to hydrogen storage. Unlike traditional adsorbents, MOFs offer a unique combination of high surface area and selective gas uptake, positioning them at the forefront of sustainable technology.

Understanding the Mechanism Behind MOFs' Superior Adsorption

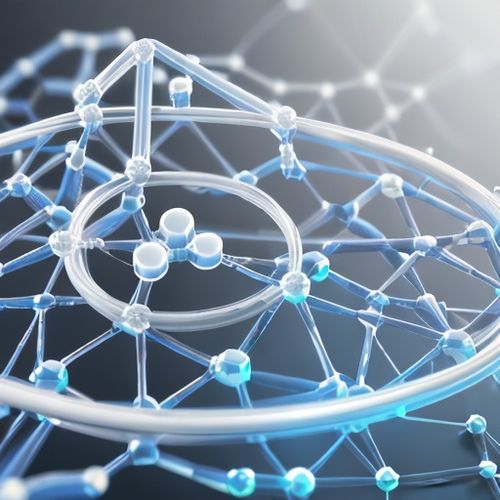

What sets MOFs apart from conventional adsorbents is their intricate design at the molecular level. The metal clusters act as nodes, while the organic linkers form the bridges, creating a porous network with exceptional surface areas—often exceeding 7,000 m²/g. This structural ingenuity allows MOFs to trap gas molecules efficiently, even at low pressures. The secret lies in the framework's ability to adjust pore size and functionality, enabling selective adsorption of specific gases like CO₂ or methane. Researchers have found that by modifying the organic ligands or metal centers, they can fine-tune the MOF’s affinity for particular gases, a feature that industrial applications are keen to exploit.

The Race for Carbon Capture Solutions

As global carbon emissions continue to rise, MOFs have emerged as a promising solution for carbon capture and storage (CCS). Their high CO₂ adsorption capacity, even in the presence of moisture, makes them superior to traditional amine-based scrubbers. Recent breakthroughs have demonstrated MOFs capable of capturing CO₂ directly from flue gases with over 90% efficiency. Companies are now investing heavily in scaling up MOF production to deploy these materials in power plants and industrial facilities. The potential to mitigate climate change while reducing energy penalties associated with CCS has positioned MOFs as a game-changer in environmental technology.

Hydrogen Storage: Overcoming the Energy Density Challenge

One of the most exciting applications of MOFs lies in hydrogen storage for fuel cell vehicles. Storing hydrogen safely and efficiently has long been a bottleneck for the clean energy transition. MOFs address this by physisorbing hydrogen molecules at cryogenic temperatures, achieving densities comparable to compressed gas tanks but at much lower pressures. Innovations in MOF chemistry, such as incorporating open metal sites, have further enhanced their hydrogen uptake capabilities. Automakers and energy companies are closely monitoring these developments, as MOF-based storage systems could finally make hydrogen-powered transportation commercially viable.

Challenges in Commercialization and Recent Breakthroughs

Despite their promise, MOFs face hurdles in large-scale adoption. Production costs remain high, and questions linger about long-term stability under industrial conditions. However, 2023 has seen significant progress on these fronts. A team at Northwestern University developed a water-stable MOF that maintains its structure after 500 adsorption-desorption cycles. Meanwhile, BASF announced a new synthesis method that cuts production costs by 40%. These advancements are critical for transitioning MOFs from lab curiosities to mainstream industrial materials. As manufacturing techniques improve and stability issues are addressed, the commercial viability of MOF-based gas adsorption systems becomes increasingly tangible.

The Next Frontier: MOFs in Gas Separation and Purification

Beyond simple adsorption, MOFs are proving revolutionary for gas separation processes. Their molecular sieving capabilities enable the separation of similarly sized molecules—a task that conventional methods struggle with. For instance, MOFs can separate ethylene from ethane with unprecedented selectivity, a process crucial for petrochemical manufacturing. Similarly, they show great promise in natural gas purification by removing nitrogen or carbon dioxide from methane streams. As global demand for high-purity gases grows across industries, MOF-based separation membranes are poised to replace energy-intensive cryogenic distillation in many applications.

Environmental Impact and Sustainable Production

The environmental credentials of MOFs extend beyond their application in carbon capture. Researchers are developing greener synthesis routes using biodegradable linkers and less toxic metals. Some teams are even exploring the use of recycled materials as MOF precursors. Life cycle assessments suggest that MOF production could become carbon-neutral within the decade, especially as renewable energy powers more manufacturing facilities. This commitment to sustainability at both the production and application stages makes MOFs particularly attractive for environmentally conscious industries and policymakers.

Looking Ahead: The Future of MOF Technology

As research into MOFs accelerates, their potential applications continue to expand. From smart sensors that detect trace gases to advanced filtration systems for air purification, the versatility of these materials seems limitless. The coming years will likely see MOFs move beyond specialized applications into mainstream use, particularly as production scales up and costs decrease. With governments and industries worldwide prioritizing decarbonization, metal-organic frameworks stand ready to play a pivotal role in shaping a cleaner, more efficient future for gas adsorption and beyond.

By James Moore/Apr 19, 2025

By Joshua Howard/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Grace Cox/Apr 19, 2025

By Noah Bell/Apr 19, 2025

By Victoria Gonzalez/Apr 19, 2025

By Amanda Phillips/Apr 19, 2025

By Samuel Cooper/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Emma Thompson/Apr 19, 2025

By Thomas Roberts/Apr 19, 2025

By Lily Simpson/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Eric Ward/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Christopher Harris/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Lily Simpson/Apr 19, 2025