The field of molecular sieve adsorption has witnessed significant advancements in recent years, driven by the growing demand for efficient separation and purification technologies across industries. Researchers and engineers are increasingly focusing on optimizing the selective adsorption properties of molecular sieves to enhance their performance in applications ranging from gas separation to catalysis. This optimization process involves a delicate balance of material design, pore structure engineering, and surface chemistry modification.

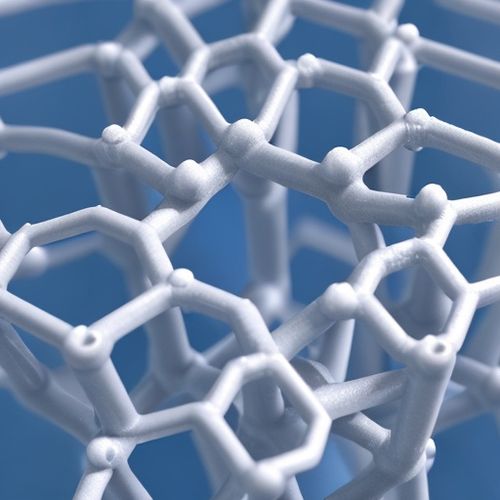

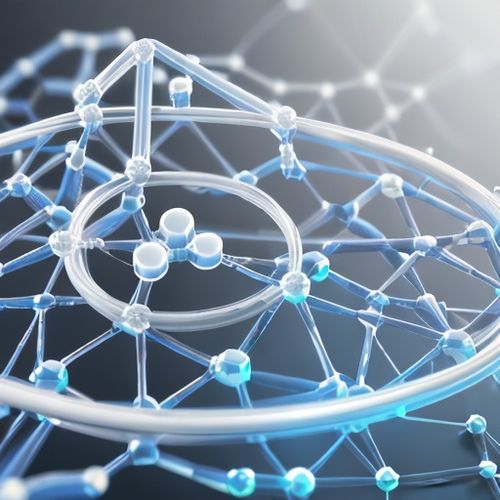

Understanding the fundamental principles behind molecular sieve selectivity is crucial for developing improved materials. These crystalline aluminosilicates possess uniform pore structures that allow them to discriminate between molecules based on size, shape, and polarity. The selective adsorption phenomenon occurs when certain molecules preferentially enter the pores while others are excluded, creating a molecular-level filtering effect. Recent studies have revealed that subtle changes in framework composition can dramatically alter adsorption selectivity, opening new possibilities for tailored separation processes.

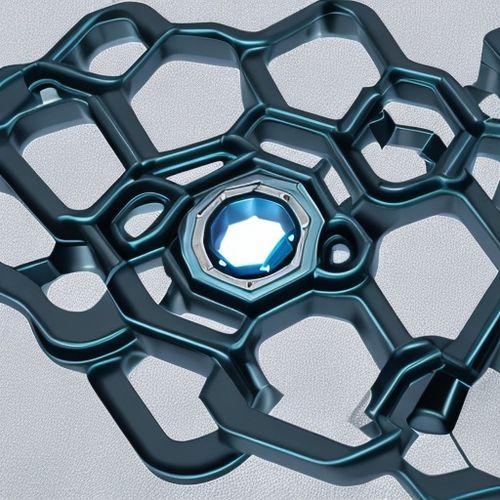

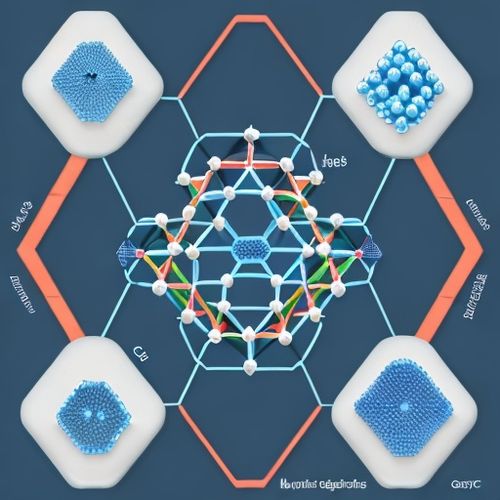

The optimization of molecular sieve adsorption typically begins with careful selection of the framework type. Zeolites with different topologies (such as FAU, MFI, or LTA) exhibit distinct pore sizes and channel geometries that determine their molecular discrimination capabilities. Researchers have discovered that introducing heteroatoms into the framework or creating hierarchical pore structures can significantly enhance both selectivity and adsorption capacity. These modifications allow for better control over the interactions between the adsorbent and target molecules.

Surface chemistry plays an equally important role in determining adsorption selectivity. The presence of cations, functional groups, or defects on the internal surfaces of molecular sieves can create specific binding sites that preferentially interact with certain molecules. Recent breakthroughs in post-synthetic modification techniques have enabled precise tuning of these surface properties. For instance, ion exchange processes can be used to introduce metal cations that form stronger interactions with polar molecules, while silanation can reduce surface polarity for improved hydrocarbon separation.

Advanced characterization techniques have become indispensable tools in the optimization process. In situ spectroscopy and diffraction methods allow researchers to observe adsorption phenomena at the molecular level, providing insights into host-guest interactions. Computational modeling has also emerged as a powerful approach, enabling the prediction of adsorption behavior and the rational design of improved materials. These tools help identify optimal operating conditions and guide the development of molecular sieves with precisely tailored properties.

The temperature and pressure conditions during adsorption processes significantly impact selectivity. Studies have shown that careful control of these parameters can enhance the separation efficiency of molecular sieves. For gas separation applications, pressure swing adsorption (PSA) and temperature swing adsorption (TSA) techniques leverage these dependencies to achieve high-purity products. Recent innovations have focused on developing molecular sieves that maintain their selectivity across wider ranges of temperature and pressure, increasing process flexibility and energy efficiency.

Industrial applications of optimized molecular sieve adsorption continue to expand. In the petrochemical industry, improved zeolite adsorbents enable more efficient separation of xylene isomers and normal/iso-paraffins. Environmental applications include the removal of volatile organic compounds from air streams and the capture of greenhouse gases. The pharmaceutical sector benefits from molecular sieves in drug purification processes, where high selectivity is essential for product quality. These diverse applications demonstrate the versatility of optimized molecular sieve materials.

One particularly promising area of development involves the creation of mixed-matrix membranes incorporating molecular sieves. These composite materials combine the selectivity of molecular sieves with the processability of polymers, offering advantages for large-scale separation processes. Researchers have made progress in addressing challenges related to sieve-polymer compatibility and interfacial defects, leading to membranes with significantly improved performance. This approach may revolutionize industrial separation technologies in coming years.

The future of molecular sieve optimization likely lies in the development of smart materials that can adapt their adsorption properties in response to environmental changes. Stimuli-responsive molecular sieves that modify their pore dimensions or surface chemistry in the presence of specific triggers could enable unprecedented control over separation processes. Additionally, the integration of machine learning techniques in materials discovery promises to accelerate the identification of novel molecular sieve compositions with exceptional selectivity.

As sustainability concerns grow, researchers are also focusing on making molecular sieve production and regeneration more environmentally friendly. Developing energy-efficient regeneration methods and exploring renewable raw materials for sieve synthesis are active areas of investigation. These efforts aim to reduce the environmental footprint of adsorption processes while maintaining or improving performance. The circular economy approach is being applied to molecular sieve lifecycle management, including recycling and reuse strategies.

The optimization of molecular sieve selective adsorption represents a vibrant field where fundamental science meets practical engineering challenges. Continued progress in this area promises to deliver more efficient, cost-effective, and sustainable separation technologies for numerous industries. As our understanding of structure-property relationships deepens and new characterization tools emerge, we can expect to see increasingly sophisticated molecular sieve materials tailored to specific separation needs. The coming years will likely bring exciting developments that push the boundaries of what's possible with selective adsorption technologies.

By James Moore/Apr 19, 2025

By Joshua Howard/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Grace Cox/Apr 19, 2025

By Noah Bell/Apr 19, 2025

By Victoria Gonzalez/Apr 19, 2025

By Amanda Phillips/Apr 19, 2025

By Samuel Cooper/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Emma Thompson/Apr 19, 2025

By Thomas Roberts/Apr 19, 2025

By Lily Simpson/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Eric Ward/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Christopher Harris/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Lily Simpson/Apr 19, 2025