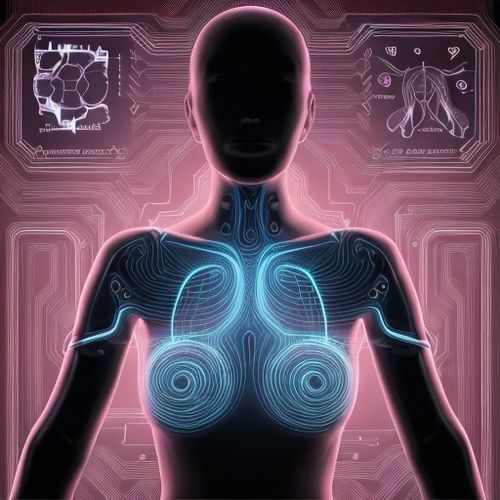

The field of wearable technology has taken a revolutionary leap forward with the advent of flexible electronic skin sensing arrays. These ultra-thin, stretchable devices mimic the sensory capabilities of human skin, opening up unprecedented possibilities in healthcare, robotics, and human-machine interfaces. Unlike traditional rigid sensors, these pliable systems conform seamlessly to curved surfaces, enabling continuous monitoring without discomfort or restriction of movement.

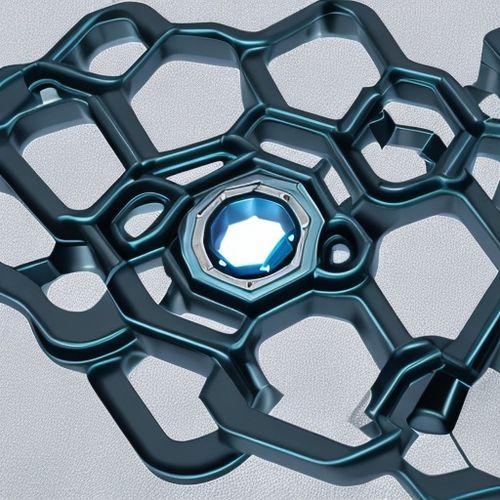

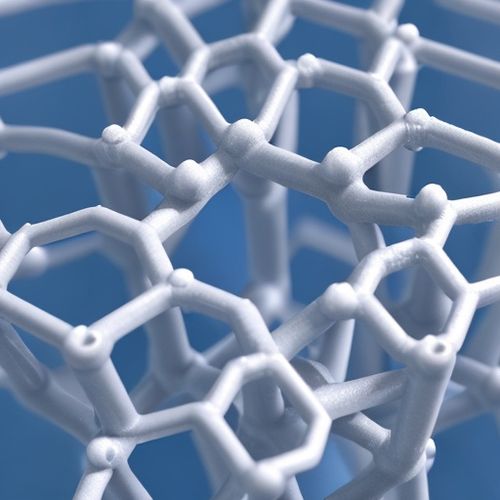

At the heart of this innovation lies a sophisticated network of microscopic sensors capable of detecting pressure, temperature, humidity, and even biochemical signals. Researchers have achieved this breakthrough through novel materials like graphene nanowires and self-healing elastomers, which maintain functionality even when stretched to 200% of their original size. The implications for prosthetics are particularly profound - amputees could soon experience near-natural tactile feedback through artificial limbs that "feel" their environment.

Medical applications currently dominate development efforts, with several research teams demonstrating continuous glucose monitoring through sweat analysis and early detection of cardiovascular abnormalities via subtle pulse wave measurements. A team at Stanford recently unveiled a prototype that maps pressure distribution across wound dressings, alerting clinicians to problematic pressure points before visible damage occurs. This preventative approach could dramatically reduce hospital-acquired pressure ulcers in immobilized patients.

The manufacturing challenges cannot be overstated. Creating durable, high-density sensor arrays that maintain accuracy after thousands of bending cycles requires pioneering techniques in nanoscale printing and materials engineering. Some designs incorporate self-assembling nanoparticle networks, while others use laser-assisted patterning to create intricate electrode meshes. Yield rates remain low for production-scale quantities, explaining why most existing prototypes exist only in laboratory settings.

Signal processing presents another formidable hurdle. Each square centimeter of advanced e-skin may contain hundreds of sensing elements, generating vast data streams that must be filtered, interpreted, and transmitted in real-time. Innovative edge computing solutions are emerging to handle this computational load locally, reducing power consumption and latency. Some systems now incorporate rudimentary machine learning to distinguish between different types of tactile information - a crucial step toward creating truly intelligent synthetic skin.

Consumer electronics companies have taken keen interest in the technology's potential beyond medical applications. Imagine smartphone screens that sense grip strength to prevent accidental drops, or gaming controllers that respond to subtle finger pressure variations. Automotive engineers envision steering wheels that monitor driver alertness through palm moisture and temperature changes. The military sees applications in enhanced flight suits that provide pilots with airflow data across their entire body surface.

Ethical considerations are coming into focus as the technology matures. Continuous biometric monitoring raises legitimate privacy concerns, while the potential for creating ultra-sensitive robotic systems invites debate about appropriate use in surveillance or security applications. Regulatory bodies are scrambling to establish testing protocols and safety standards for devices that will remain in prolonged contact with human skin.

Commercialization efforts are accelerating, with venture capital flowing into startups specializing in specific components like stretchable batteries or biocompatible adhesives. Industry analysts predict the first clinical-grade e-skin products could reach specialized medical markets within three years, followed by consumer applications about two years later. The current price point remains prohibitive for mass adoption - a single palm-sized sensor array can cost thousands to manufacture - but economies of scale and material innovations should drive costs down substantially.

Looking ahead, researchers are working toward integrating multiple sensing modalities into single platforms. The holy grail would be a unified system that simultaneously monitors mechanical, thermal, chemical, and electrophysiological signals with clinical-grade accuracy. Some teams are experimenting with wireless power harvesting to overcome battery limitations, while others explore biodegradable versions for temporary medical monitoring. As material science and microfabrication techniques continue advancing, flexible electronic skin may soon become as ubiquitous and indispensable as the smartphone.

The convergence of nanotechnology, advanced materials, and artificial intelligence makes this one of the most dynamic frontiers in modern engineering. What began as speculative research in university labs has blossomed into a multidisciplinary race to create the most sophisticated artificial sensory system ever devised. The implications extend far beyond current applications - we may be witnessing the birth of an entirely new paradigm in how humans interact with technology and understand our own biological systems.

By James Moore/Apr 19, 2025

By Joshua Howard/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Grace Cox/Apr 19, 2025

By Noah Bell/Apr 19, 2025

By Victoria Gonzalez/Apr 19, 2025

By Amanda Phillips/Apr 19, 2025

By Samuel Cooper/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Emma Thompson/Apr 19, 2025

By Thomas Roberts/Apr 19, 2025

By Lily Simpson/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Eric Ward/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Christopher Harris/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Lily Simpson/Apr 19, 2025