The natural world has long served as an inspiration for scientific breakthroughs, and the field of hydrophobic materials is no exception. Recent advancements in biomimetic hydrophobic materials have demonstrated remarkable potential, driven by intricate structural optimizations that mimic nature's most water-repellent surfaces. From lotus leaves to butterfly wings, researchers are decoding biological blueprints to engineer surfaces that defy wetting with unprecedented efficiency.

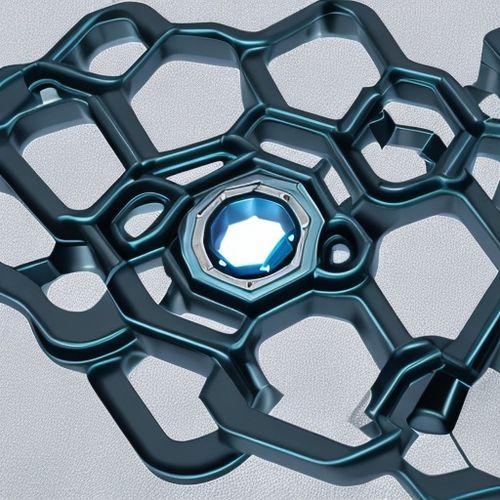

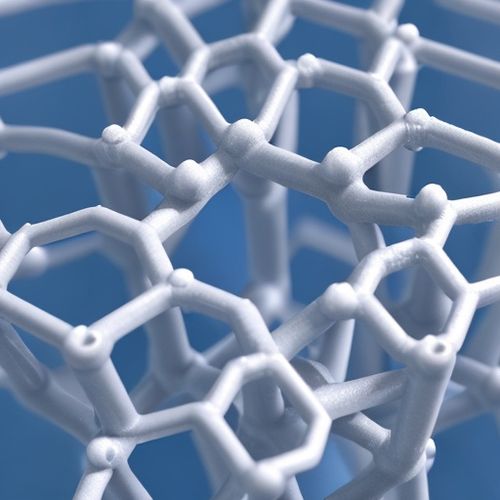

At the heart of this innovation lies the sophisticated interplay between micro- and nano-scale architectures. The lotus effect, perhaps the most celebrated example of natural hydrophobicity, owes its properties not just to surface chemistry but to a hierarchical structure of wax-coated papillae. Scientists are now recreating these complex topographies through advanced fabrication techniques, achieving contact angles exceeding 150° while maintaining mechanical durability that surpasses natural counterparts.

Precision engineering has emerged as the cornerstone of structural optimization in synthetic hydrophobic materials. Where early attempts relied heavily on chemical coatings, contemporary approaches focus on tailoring surface geometries at multiple length scales. Electron beam lithography and plasma etching enable the creation of precisely controlled pillar arrays, while self-assembly techniques produce stochastic nanostructures that mimic biological randomness. This dual-scale roughness proves critical for maintaining superhydrophobicity under varying environmental conditions.

The aviation industry provides a compelling case study for applied biomimetic hydrophobicity. Aircraft surfaces optimized with dragonfly wing-inspired patterns demonstrate significantly reduced ice accumulation during flight. Unlike traditional de-icing systems that consume substantial energy, these passive solutions maintain performance through clever air pocket preservation within their microscopic textures. Field tests show ice formation delays of up to 40 minutes in freezing rain conditions - a breakthrough with profound safety implications.

Durability challenges that once plagued hydrophobic surfaces are being overcome through structural innovations. The traditional trade-off between water repellency and mechanical robustness is being addressed by borrowing design principles from desert beetle exoskeletons. These incorporate flexible microdomes that redistribute stress while maintaining surface heterogeneity. Laboratory abrasion tests reveal some bio-inspired coatings retain superhydrophobicity after 10,000 cycles of standard wear testing, bringing practical applications within reach.

Marine applications are witnessing particularly transformative developments. Ship hulls incorporating shark skin-derived patterns demonstrate not only fouling resistance but also hydrodynamic advantages. The micro-riblet structures reduce skin friction drag by up to 8%, while the self-cleaning properties diminish biofouling without toxic antifouling paints. Computational fluid dynamics simulations guide the optimization of these textures for specific vessel types, balancing water repellency with flow characteristics.

Energy sector applications are pushing the boundaries of what hydrophobic surfaces can achieve. Solar panels with moth-eye inspired nanostructures maintain cleaner surfaces for longer periods, with field data showing 5-7% efficiency gains in arid environments. More remarkably, power plant condensers employing optimized hybrid structures report 20% improvements in heat transfer efficiency - a feat accomplished by precisely controlling droplet formation and shedding patterns on the nanoscale.

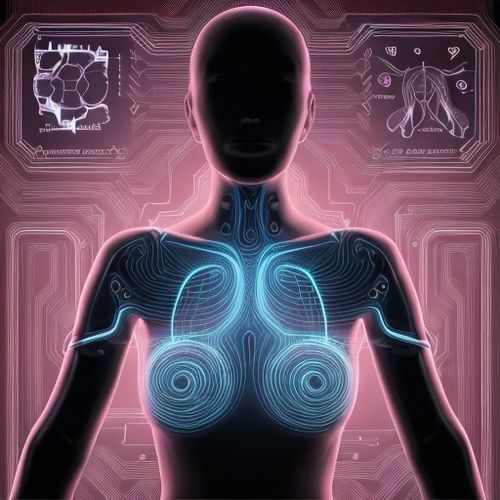

The medical field presents perhaps the most delicate balancing act for hydrophobic surface design. Implantable devices now benefit from mosquito proboscis-inspired textures that prevent protein adhesion while maintaining biocompatibility. These carefully tuned surfaces reduce thrombosis risk without compromising cellular integration. Recent trials of vascular stents with optimized micro-patterns show 60% reduction in platelet adhesion compared to conventional surfaces.

As research progresses, the focus is shifting toward dynamic hydrophobic surfaces that can adapt to environmental changes. Inspired by the stomata of plants, new generations of materials can modulate their wettability in response to temperature, humidity, or electric stimuli. These "smart" surfaces maintain optimal performance across diverse conditions, opening possibilities for applications ranging from adaptive clothing to microfluidic devices.

Manufacturing scalability remains the final frontier for biomimetic hydrophobic materials. While laboratory successes abound, translating intricate biological designs into cost-effective production requires innovative approaches. Roll-to-roll nanoimprinting and 3D hierarchical printing show particular promise, with several startups now commercializing nature-inspired water-repellent surfaces for consumer products.

The future of hydrophobic materials lies in deeper biological insights coupled with advanced fabrication capabilities. As researchers continue to decode nature's structural secrets and develop tools to replicate them, we stand on the brink of a new era where water-repellent surfaces become ubiquitous - from our clothing to our skyscrapers, all bearing the subtle but profound imprint of biological wisdom.

By James Moore/Apr 19, 2025

By Joshua Howard/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Grace Cox/Apr 19, 2025

By Noah Bell/Apr 19, 2025

By Victoria Gonzalez/Apr 19, 2025

By Amanda Phillips/Apr 19, 2025

By Samuel Cooper/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Emma Thompson/Apr 19, 2025

By Thomas Roberts/Apr 19, 2025

By Lily Simpson/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Eric Ward/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Natalie Campbell/Apr 19, 2025

By Christopher Harris/Apr 19, 2025

By Sophia Lewis/Apr 19, 2025

By Lily Simpson/Apr 19, 2025